Conveyor technology for every task

As diverse as the workpieces, products and production lines, is our cross-divisional portfolio in the field of Conveying systems, with which we efficiently and flawlessly answer every task for every industry.

TRAPO grew up with expertise in materials handling technology – to this day, we supply customized elements of materials handling technology for every task in order to sustainably optimize the flow of materials in production and intralogistics. The solutions are based on the tasks of the industry – with special expertise for conveying in clean-room environments.

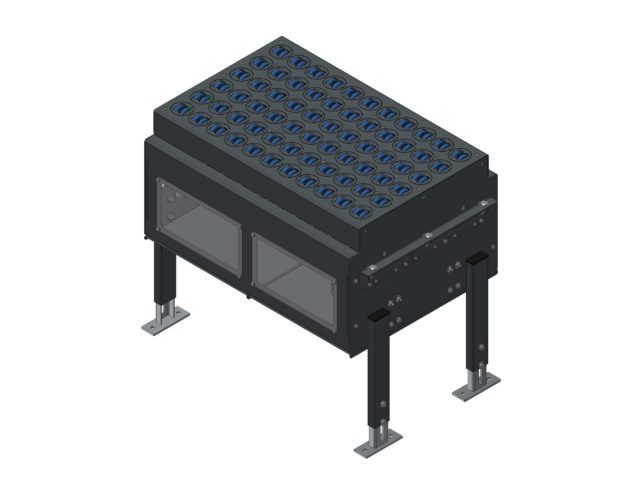

Get to know and appreciate the latest generation of conveyor technology: Modular belt conveyors, transfer conveyors, all-side roller conveyors, discharge and distribution stations, rotary and collecting tables, belt conveyors, chain and belt conveyors, slat-band conveyors, roller and vertical conveyors, and empty and full pallet conveyors.

Advantages

- Conventional, autonomous or combination

- Customized elements

- Individual, cross-product and cross-sector solutions

- Special designs in hygienic design