High-performance kinematic picker: innovative pick and place solution

Kinematics transcends limits and offers more possibilities for picker application. With enormous stroke and extended radius, the kinematics solution ensures consistently high process quality, machine availability and enormous cycle rates.

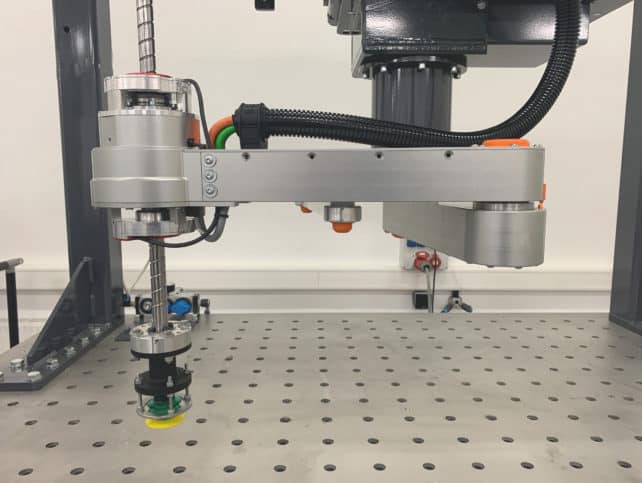

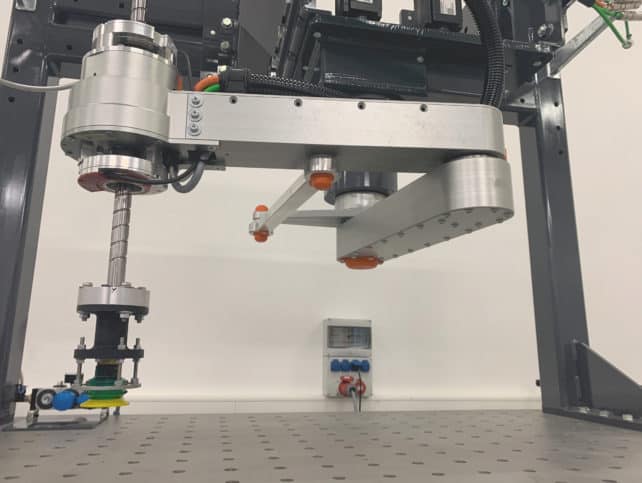

The high-performance parallel kinematics consists of a five-member kinematic structure, a Z-axis and a rotary module for orientation. Developed by teams from TRAPO Test Center and RWTH Aachen University.

The modular system has an optional three or four degrees of freedom. Named for the high performance of the HPPS series, the high-speed pick-and-place system is used with up to 200 parts/min and with up to five kilograms of payload.

24/7 High Performance and Absolute Precision

The 3 payload classes of the HPPS series handle wet, dry or irregularly shaped food as well as primary and secondary packaging.

Load class 1 kg

For small and very light products that can be picked up with a single

can be picked up with a single suction cup

Load class 3 kg

For cylindrical bags or cans that can be either suctioned or

gripped

Load class 6 kg

Allrounder: for products that are either sucked or gripped

(All payloads refer to gripper plus product)

High-performance parallel kinematics consists of a five-link kinematic structure, a Z-axis and a rotary module for orientation. Developed by teams from the TRAPO Technical Center.

Advantages

- Innovative Gripper and kinematics from one source, one control software without internal interfaces

- Optional large radius of action (800mm) or large stroke (200mm)

- Kinematics replaces delta or articulated arm robots

- Output up to 200 picks/min.

- Payload up to 5kg

- Modular system

- In-house gripper development and production

- Picker cell can be expanded at any time

Technical details

- HPPS 200

The HPPS 200 replaces the conventional picker

Parallel kinematic picker with 4 axes

Performance:

max. 200 picks/min. per kinematics

Payload: up to 5kg (incl. gripper)

Large operating radius (800mm) and large stroke (200mm)

Dead weight: 105kg

Picker cell dimensions: min. 2 x 2 x 2m

Power supply: 400V

Power supply at the flange for the gripper: pneumatic and electric

Direct drive of the lifting and rotating unit by torque motors

Modular design of the high-performance picker line; can be expanded at any time

Hygienic design:

Parts are coated for the food industry. Bending of the components and more

No interfaces:

1 System I 1 Control: Gripper and kinematics from a single source; only one control software for the kinematics

Individual gripper technology:

In-house gripper development and production

Flexible feeding of trays for depositing products

Multifunctional application:

Remove – transfer – sort – pack