Precision and high performance

for pick and place systems

In order to pick up and move products with repeatable accuracy, the use of pick and place systems is recommended. They constantly perform the same movement 24 hours a day at maximum performance and with absolute precision, thus ensuring consistently high quality, availability and cycle rates.

Pick and Place: Decide between several options

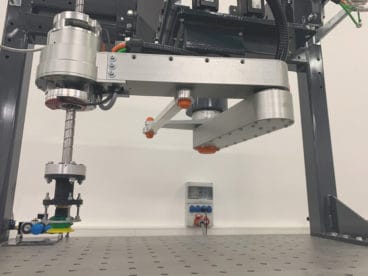

Kinematic-Picker

TRAPO high performance pick and place solution with large work area.

View product

Picker with delta or articulated arm robots.

Pick and place solutions with third-party delta or articulated arm robots.

View product

Mix tray formation with picker

TRAPO solution for forming mixing trays.

View productReduce production time with picker solutions

Every automated picker solution takes into account the product-specific production scenario, for example use in the care sector etc.. The task: to pick up and place components or materials. For this purpose, they are equipped with the appropriate load capacity. In addition, each picker unit is supplemented by state-of-the-art gripper technology to pick products at high speed on the clocked conveyor belt with consistent precision.

By automating pick and place or sorting tasks, manufacturers optimize their production processes. In addition, for manufacturers this means optimum efficiency in production, shorter throughput times, less waste, the sustainable relief of people from monotonous tasks and the reduction of errors.