High-performance layer palletizer impresses in the tightest of spaces

With the HLP 6000 high-performance layer palletizer, TRAPO is presenting a modular system that can be adapted to any space situation and that acts flexibly in terms of product and industry at any position within production.

The compact layer palletizer deposits perfectly and realizes any layer patterns of different formats – up to ten layers per minute.

The HLP 6000 serves an almost unlimited product range: highly flexible, as it can be adjusted to any product. This means that perfect, clean layers and piles can be formed under maximum performance with a wide product variety from the customer and different formats.

With this considerable advantage, the HLP shows off its unique selling point, absolute flexibility: Until now, a great deal of modification work was required to implement complex layer patterns.

The basic modules of the HLP 6000 are the lifting column, the layer gripper and the infeed section. The HLP 6000 is available in three variants:

Advantages

- Small footprint

- Extremely compact palletizer

- Modular system

- Multiple infeeds

- Bottom/top infeed

- Wide range of layer pad designs

- High speeds

- Possibility of palletizing on several palletizing stations

- Palletizing capacity of up to ten layers per minute

- Clean pallet image due to centering of the products in the gripper

Precisely distribute products and form layers

Precise layer formation is the basis for ensuring that loads are optimally secured on their journey to intermediate storage or in intermodal transport to their destination. A wide variety of products are moved and precisely positioned depending on their nature.

The automation of partial and complete systems requires adjustments in the effectiveness and performance of palletizing tasks. In the infeed area, depending on the product and the task, the flexible, omnidirectional OMNI CON® table, the high-performance parallel kinematics of the HKS series with intermittent conveyor, or conventional methods form the layers as a preliminary stage to palletizing.

Once the layer pattern and product dimensions have been specified, the kinematics and OMNI CON® program themselves – thanks to TRAPO’s own software.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Technical Details

- HLP 6000

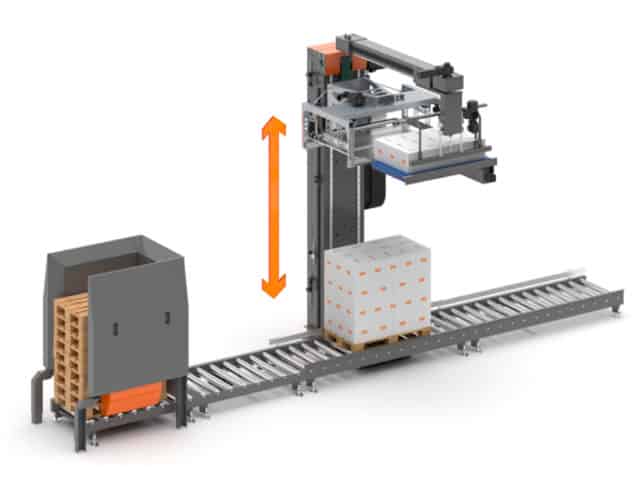

- HLP 6000 basic variant

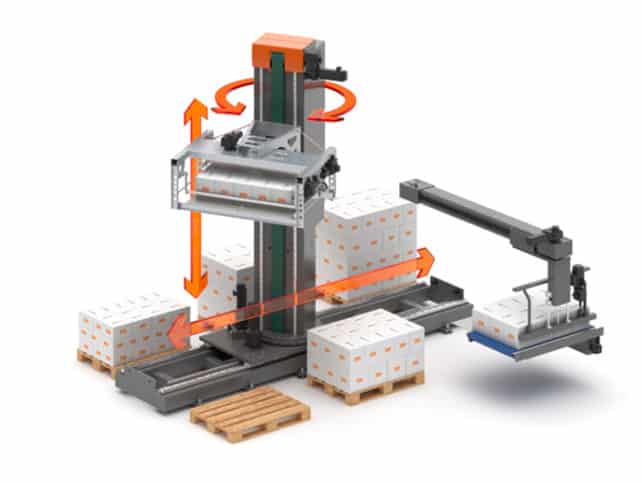

- HLP 6000 with Y-axis

- HLP with rotary module / traversing axis or combination of both

HLP 6000 with top infeed area and bottom palletizing station

The HLP 6000 with Y-axis serves several palletizing stations, in-feed area at the bottom or top, palletizing stations at the bottom

HLP with rotary module / traversing axis or combination of both: traverses along a given length; the rotary variant operates in a radius of 180°

Modular system

Performance:

Up to 10 layers/min.

Layer weight:

Up to 200 kg

Palletizer net weight:

1950 kg

Power supply:

400V

Low friction recirculating ball-bearing guides

Low space requirement / extremely compact

Different pallet formats (Euro, industrial, Chep etc.) possible with one layer gripper without mechanical conversion

Possibility to palletize different products by type

Different layer pad designs

Integrated drop guarding

Equipment of the palletizing stations with gangway and maintenance stations

For the care sector in stainless steel design

Low space requirement / extremely compact

Different pallet formats (Euro, industrial, Chep etc.) possible with one layer gripper without mechanical conversion

Possibility to palletize different products by type

Different layer pad designs

Integrated drop guarding

Equipment of the palletizing stations with gangway and maintenance stations

For the care sector in stainless steel design