Automation in the chemical and petrochemical industry

Safety is paramount in automation in the chemical and petrochemical industry. We know the requirements for production, handling and transport of bulk materials. TRAPO solutions offer – even in corrosive atmospheres – maximum process safety, reliability, transparency and plant availability.

Our solution for your products

Whether bulk goods in bags, liquids in buckets or powder in cartons: TRAPO takes care of the safe handling.

Product portfolio

Palletizing and depalletizing

For effective palletizing and depalletizing of bulk materials, we implement any desired layer pattern.

See in actionPalletizing and depalletizing

Palletizing robots for high-performance applications

Products of the chemical and petrochemical industry are palletized at high speed. The TRAPO GmbH robot achieves a maximum performance of 1200 bags per hour when palletizing them in different sizes and weights. Individual gripper systems ensure stable, secure layers and perfect stacks as the basis for intermodal transport.

See product

Pick and Place

We configure the perfect pick and place application.

See in actionPick and Place

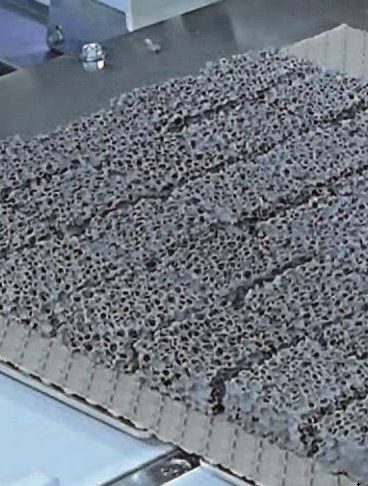

Automated: Picking and packing ceramic filters

Whereas ceramic filters were previously palletized in cartons by hand due to the high risk of breakage, this task is now performed by three picker lines. During feeding, cameras scan the position and orientation. Based on this information, pickers pick up the ceramic filters via a suction pad, transfer them to a nonwoven blank and place them there. The full stacks from all lines are fed to the fully automatic packaging system via a transfer carriage.

See product

Carton filling

Packing in cartons - including instruction leaflet and quality control.

See in actionCarton filling

Top performance for packing in cartons

With the TRAPO Packing System (TPS series), TRAPO is a pioneer in using innovative high-performance kinematics for the further packing of primary packaging. In the variant with a large radius of action, the picker has a rotationally symmetrical working area thanks to its parallel kinematic design and can reach far behind itself.

See product

Load securing

Wrapper with low film consumption - for stable transport units.

See in actionLoad securing

Intermodal Transport: Pallet Securing with Wrapper

Petrochemical products, fertilizers and more: Palletized bags of chemical or petrochemical products are secured fully automatically by the TRAPO Stretch Wrapper (TSW series). In the process, the entire pallet is wrapped with film at high speed – this is how manufacturers ensure the required transport security.

See product

Automated guided vehicles

Safe, autonomous pallet transport for products in the chemical industry.

See in actionAutomated guided vehicles

Driverless pallet transport for the chemical industry

With the use of driverless shuttles, TRAPO GmbH is opening a new chapter of flexible conveyor technology for the chemical and petrochemical industry. As a partner in industrial automation, the TRAPO Transport Shuttle (TTS series) offers new, flexible competence between production and warehouse to safely transport pallets of plastic products.

See product

Warehousing

Safely stored - provided on demand

provided: automated warehouse.

Warehousing

TRAPO competence in the warehouse

At the high-bay warehouse, one or more TRAPO Warehouse Shuttle goods (TWS series) take over goods as required. The TWS accelerates at 1.5 m/s² and completes the cycle of extending, gripping and retracting in a maximum of three seconds. The racking system is modular and flexibly expandable. Consequently, performance can be significantly increased at any time with additional TWS and additive lifting devices.

See product

Autonomous loading and unloading

Safe, continuous, autonomous loading and unloading.

See in actionAutonomous loading and unloading

Eliminating forklift traffic: autonomous loading and unloading

The TRAPO Loading System (TLS 3600) is a driverless, compact transport system with a lifting unit that can load three pallets simultaneously into a truck or, for intermodal transport, into an overseas container. In the process, it corrects its position automatically. This continuous loading process saves time and distance and allows a 13-meter trailer to be loaded with 33 pallets in about 15 minutes. Of course, this process can also be run through in reverse order for unloading trucks.

See product

Conveying technology

Conveyor technology including accessories: scales, labeling systems, equalizing systems and more.

See in actionConveying technology

We gently convey sacks, canisters and palletized goods

Modular belt conveyors, transfer conveyors, all-side roller conveyors, discharge or distribution stations and more: We also manufacture the optimum conveyor line for your industry and your products – for example, for sacks, buckets, canisters, empty and full pallets. Today, rigid, tried-and-tested components are just as much part of the range as mobile conveyor lines. Made in Germany – the entire portfolio of conveyor systems is manufactured at our headquarters in Gescher-Hochmoor.

See product

Chemical and petrochemical industry 4.0

Data management answers chemical industry safety requirements.

See in actionChemical and petrochemical industry 4.0

Plan maintenance and personnel deployment proactively

Use TIM, the TRAPO Intelligent Management System, to get the most out of your plant throughout its entire life. TIM can be integrated into existing ME and ERP systems and provides important data around the clock – so you can initiate optimization at any time.

See product