AMR: Patented modules for safe pallet and box transportation

MOVELI’s solutions are designed to accelerate and optimize the efficiency of warehouse and production facilities in various industries. MOVELI offers add-on modules for autonomous mobile robots (AMR), which are developed in Switzerland. They set new standards in the handling of boxes and pallets.

Advantages

- Advanced alignment system for high handling performance

- Designed for collaborative environments

- Simplified installation

- Quick relocation to new sites

- Increased workplace safety / ergonomic working height

- Compatible with AMR from major manufacturers

- For green and brownfield installations

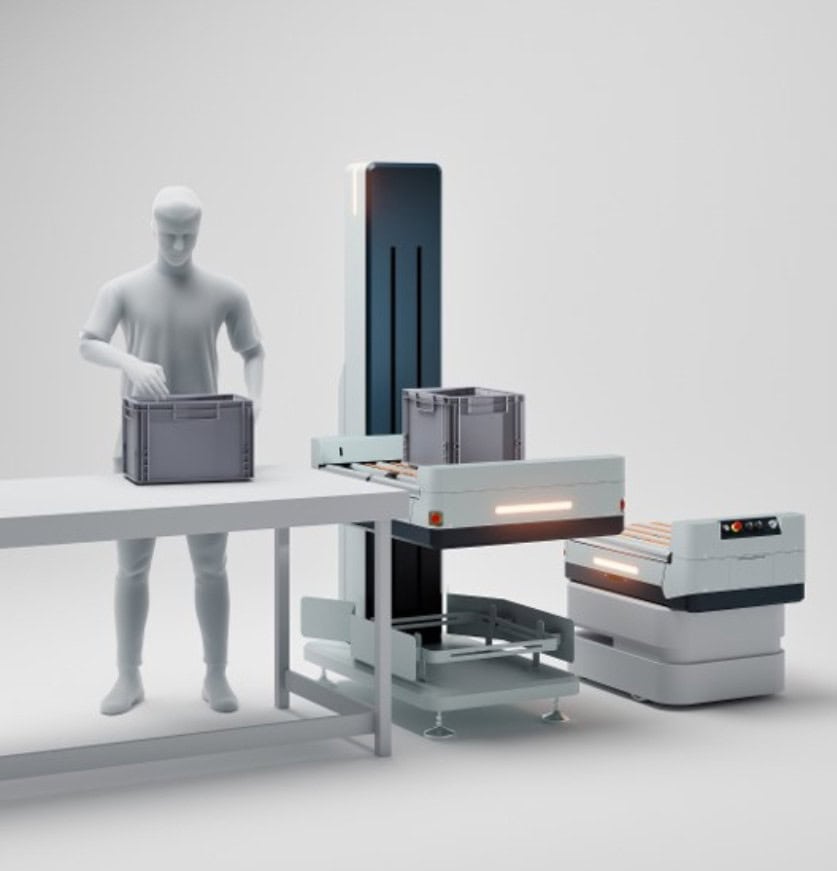

MOVELI Box Solution use cases

Ergonomic benefits

Manual loading and handling of boxes to be shipped to location X.

Plug-and-Play AMR logistics

Connection to existing automation or robot cells.

Handling of loaded and empty cartons simultaneously or on several levels from A to B.

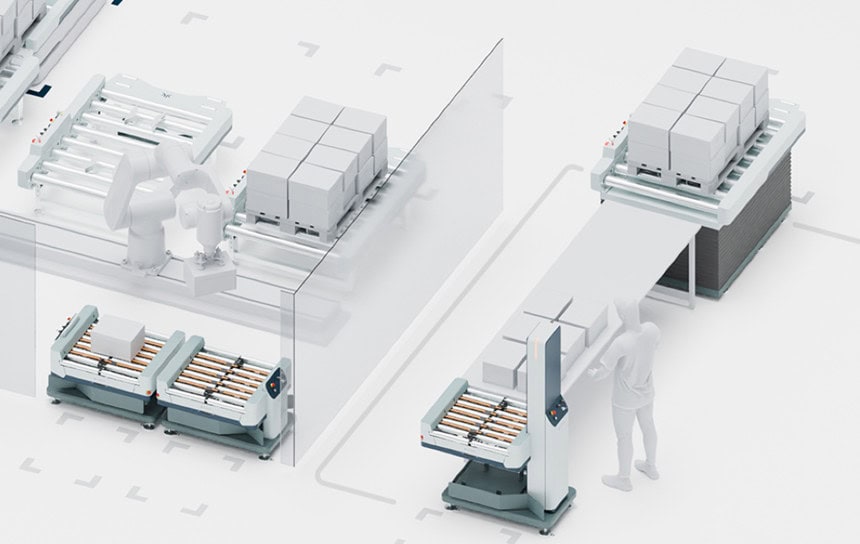

MOVELI Pallet Solution use cases

Collaborative and safe

De-/palletizing with a robot arm or a person, so that each crate is handled with the AMR while maintaining ergonomics.

Space-saving multi-level conveyors

Simultaneous handling of loaded or empty pallets during storage

Ideal scenarios for MOVELI

The use of MOVELI is ideal for

- For applications that require a low to medium throughput

- For small to medium sized manufacturing facilities (SMEs) where manual handling is predominant

- For industrial plants that have automation needs; AMRs are cost-effective solutions (compared to conveyor belts, robotic cells, etc.), modular solutions that can be adapted to customer-specific layouts

- For (smaller) greenfield facilities that have an immediate need (short lead time) for automation and require evolving solutions over time

- In installations that have a smaller number of loading and unloading points but a considerable distance between them

- In plants that have machines and conveyors at different heights

- In plants where payloads with different orientations and sizes are handled

- Where the ergonomics of people play a role

- Where the quality of material handling is crucial

- Where the safety of work processes is of the utmost importance

Technical details

Moveli Box Solution

Payload type EU boxes

600 x 400, 400 x 300, 200 x 300 mm

Payload range up to 65 Kg

Dock lift height from 500 to 1200mm

Dock in lift and no-lift configurations

Front and side-docking:

optimized maneuvering and loading/unloading of boxes –> throughput

Box rotation on dock:

free choice of box orientation

Active alignment with sensors for higher transfer reliability

Safety:

Certified together with the AMR

Designed and equipped with state-of-the art safety mechanisms

Includes QR code, RFID, barcode readers as required

Moveli Pallet Solution

Payload type EPAL – 1/2/3

Payload range up to 1200kg

Dock lift height from 400 to 1200mm

Dock with lift and no-lift configurations

Front-docking

Safety:

Certified with the AMR

Dock with built in safety elements and facility interface

Lightweight and compact Upper module:

Longer battery life and higher throughput

Includes QR code, RFID, and barcode readers as required

- Modular design that handles payloads of different sizes, orientations and weights

- Direct communication between the Upper and Dock modules, requiring minimal software integration